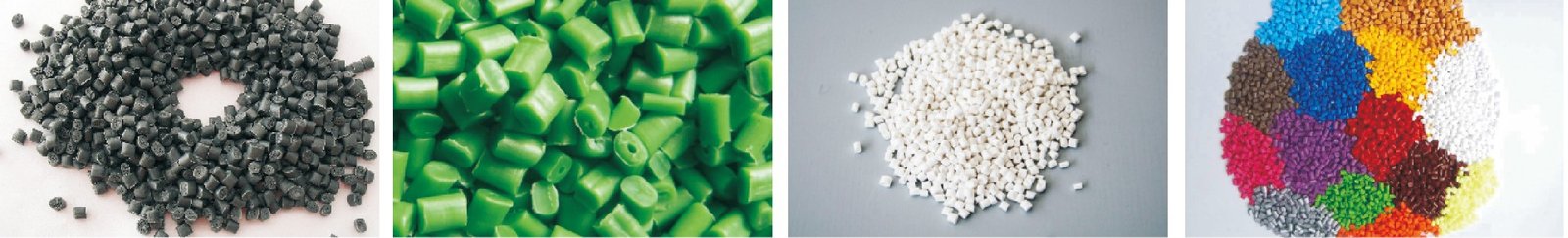

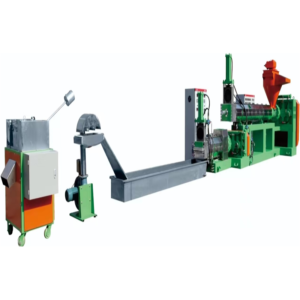

PVC SPVC WPC Compounding Counter-rotating Parallel Twin Screw Granulator

Counter-rotating Parallel Twin Screw Granulator is widely used in PVC cable modification, PVC powder blending, PVC film, etc.

Feature of Machine:

-Touch screen control panel or control by temperature controller

-User friendly software developed by European standard

-High-torque gearbox (Original made in European)

-Screw internal water thermal regulation (Original made in European)

-Equipped with degassing zone

-Different material feeding options for stable production of PVC-U powder

-All commercial parts made in Turkey and Europe

This pelletizing machine is composed by a counter parallel twin-screw extruder and downstream equipment, it is suitable for the pelletizing of PVC soft and rigid,The pellets produced by this machine is evenly, solid, elegance. The pelletizing down-stream equipment is the die face cutter, air transferring unit, vibration separating and cooling unit.

This pelletizing down-stream equipment has the features of high automation and high production efficiency.

1.PVC pelletizing line is one of our main products, which has the advantages of high stability,better capacity at reasonable consumption.

2.The pelletizing line includes extruder, pelletizing mould, air cooling sytem and vibrosive.

3.All our extrusion equipments are using best standard devices. eg. ABB frequency invertor, which enjoys global guarantee, Simens standard main motor, Schneid er buttons, Japanses RKC temperature indicators, ABB frequency controller. Feeding powder motor is controlled by ABB .If PVC pelletizing are color concentrate, we can add three or five stock bins.

Main Technical Parameters:

| SJSZ45/90 | SJSZ51/105 | SJSZ55/110 | SJSZ65/132 | SJSZ80/156 | SJSZ92/188 | |

| Screw Diameter (mm) | 45/90 | 51/105 | 55/110 | 65/132 | 80/156 | 92/188 |

| Driving motor (kw) | 15 | 18.5 | 22 | 37 | 55 | 110 |

| Output (kg/h) | 70 | 100 | 150 | 250 | 400 | 750 |

| Central height (mm) | 1000 | 1000 | 1000 | 1000 | 1100 | 1200 |

| Rotating speed (rpm) | 1-45 | 1-45.5 | 1-40 | 1-38 | 1-36.9 | 1-34.7 |

| Weight (kg) | 2800 | 3000 | 3500 | 4000 | 5000 | 6000 |

| Dimension (mm) | 3360*1290*2150 | 3400*1290*2150 | 3620*1350*2200 | 3900*1520*2450 | 4750*1600*2480 | 6700*1600*2650 |

FAQ:

1.How about your products warranty ?

One year(12 months) Warranty will be provide from the date of container arrive Clients’factory.If machine parts are broken due to quality problem within warranty period, we will send new part for free( Any artificial misuse or destory prepensely is not included within the limitation of Quality Guarantee).

2.What are your Payment and delivery terms?

Payment term:

1) T/T, 30% as prepaid ,70% before delivery

2) L/C, 30% by T/T ,70% as L/C at sight

Delivery time: Standard will be in 30-40 working days

3.What Technical Support we can get if order machines?

We can provide Installation Drawings,Basic operating instructions,Operation explanation through Video&Photos,Online video calling for technical support if necessary.

نقد و بررسیها

هنوز بررسیای ثبت نشده است.