Paper Bowl Making Machine

The full-automatic PE film coated paper bowl machine is a multi station automatic forming machine. It has continuous processes such as automatic paper feeding (printed fan-shaped paper), sealing (heat sealing paper cup wall), oil injection (upper winding mouth lubrication), bottom punching (automatic blanking cup bottom from web paper), heating, knurling (cup bottom sealing), crimping and cup unloading collection, as well as photoelectric detection, fault alarm ,counting and other functions.

| Name | Automatic single tray paper bowl machine | |

| Model | WX-D800 | |

| Paper Bowl Size | MAX. 1400 ml | |

| Raw Material | Single and double coated paper | |

| Speed | 60-70 pcs/min | |

| Suitable paper weight | 160-300g/m2;±20g/m2 | |

| Voltage supply | 380V(220V) 50HZ | |

| cup size | Bottom 80-125mm, upper diameter 100-148mm, height 125mm | |

| Working Air Source | 0.4-0.6Mpa; 0.4m³/min | |

| General power | 12kw | |

| Net weight | 2800kg | |

| Measurement (mm) | Main | 2350x1320x1900 Bowl receiving manipulator |

| Dish rack | 100kgs | |

| Cup Side Sealing | EVERGREEN Ultrasonic | |

| Bottom Knurling | HOT AIR SYETEM | |

| The mold can be customized according to customer requirements | ||

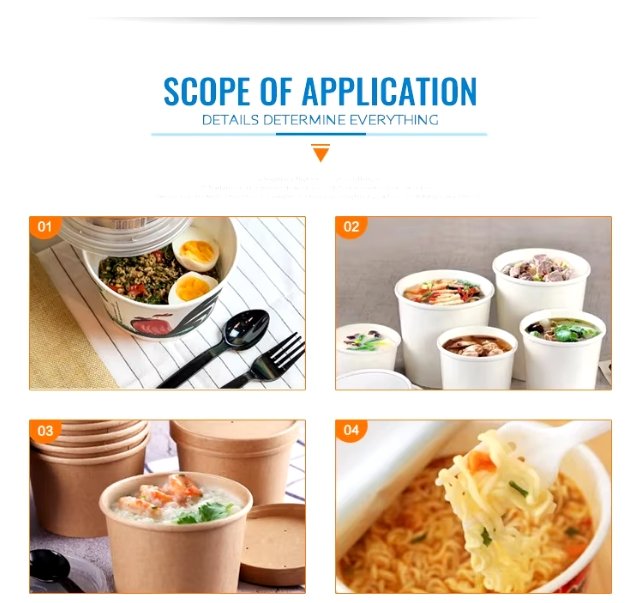

Application:

It can produce paper bowls, breakfast bowls, instant noodle bowls, takeaway bowls, soup bowls and cold drink paper bowls, etc. Suitable for manufacturers of disposable paper tableware.

Features:

- The machine has a high degree of automation, automatic paper feeding, sealing, oil filling, bottom punching, heating, knurling, edge curling and paper bowl collection can be completed at one time.

- Investment prospect of automatic paper bowl machine: the market demand is large, and it is suitable for the environmental protection demand of social development.

- The machine occupies a small area, consumes less power, and is easy to operate, which can be operated by one person.

- Change different molds to produce products with different shapes and specifications.

- The display screen supports multiple languages, can store multiple sets of parameters, and the manual control button is easy to operate.

- Emergency stop button (safety first, if there is an unexpected situation, the machine can be stopped immediately).

- The paper bowl machine adopts stepless frequency conversion speed regulation, which can easily adjust the speed of the paper bowl machine equipment during the production process.

- The paper bowl machine adopts photoelectric monitoring, which can actively alarm and count faults.

- Vacuum suction conveying device, which automatically conveys the printed fan-shaped paper forward.

- The bowl body is bonded by ultrasonic heat sealing, which will not damage the printing surface and has high efficiency.

- The machine has a complete set of automatic lubrication system, which can automatically add lubricating oil to the moving parts of the whole machine. It saves time and effort, has higher efficiency and longer service life of the machine.

- The machine is equipped with guardrails, safety first, to protect people from harm.

Fikr-mulohazalar

Baho berilmagan.