Product Description:

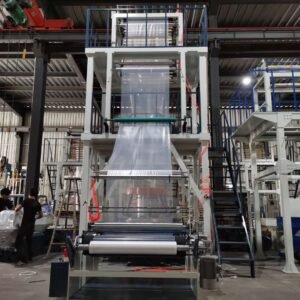

PE Hot Shrinkable film Extruder /PE heat shrink film blowing machine packaging machine

Usage:

It is used to blowing low density polyethylene (LDPE), high density polyethylene (HDPE) and linear low density polyethylene (LLDPE) and other plastic films. It is widely used in liquid packaging, printing compound, clothing textile packaging, industrial packaging, etc.

Main Technical Parameters:

| Model | WX-SF45 | WX-SF-50 | WX-SF55 | WX-SF60 | WX-SF65 | WX-SF80 | WX-SF100 |

| Screw diameter | 45mm | 50mm | 55mm | 60mm | 65mm | 80mm | 100mm |

| Screw ratio (L/D) | 28:1 | 28:1 | 28:1 | 28:1 | 28:1 | 28:1 | 28:1 |

| Screw speed | 10-100r/min | 10-100r/min | 10-100r/min | 10-100r/min | 10-100r/min | 10-100r/min | 10-100r/min |

| Main output | 20-30kg/h | 25-35 kg/h | 35-50 kg/h | 55-65 kg/h | 55-70 kg/h | 70-90 kg/h | 110-140 kg/h |

| Power of main motor | 7.5kw | 7.5-11 kw | 11-15 kw | 15-18.5 kw | 18.5-22 kw | 30-37 kw | 45-45 kw |

| Specification of die head | φ40-80mm | φ60-120mm | φ100-170mm | φ100-170mm | φ120-220mm | φ150-300mm | φ500mm |

| Rotational mode of machine head | Continuous rotation | Continuous rotation | Continuous rotation | Continuous rotation | Continuous rotation | Continuous rotation | Continuous rotation |

| Single-side thickness | 0.01-0.10mm | 0.01-0.10mm | 0.01-0.10mm | 0.01-0.10mm | 0.01-0.10mm | 0.01-0.10mm | 0.01-0.10mm |

| Max.folding width | 600mm | 600mm | 800mm | 1000mm | 1100mm | 1500mm | 2000mm |

| Total power | 19.5kw | 22kw | 26kw | 30kw | 42kw | 56kw | 88kw |

| Weight of machine | 1900kg | 2000kg | 2300kg | 2000kg | 3800kg | 4600kg | 6000kg |

| Overall dimensions (m) | 4.5*1.8*3.5 | 4.5*1.8*3.5 | 5.5*2*3.8 | 6*2.2*4.2 | 6*2.4*4.3 | 7*2.7*5.8 | 8*3.2*7.6 |

Main Features:

A, Main motor and take-up motor are controlled by frequency inverter adjust

B, Material of screw and barrel: 38CrMoAlA Polished with Nitride Treatment

C. hardness of heat treatment: screw HV≥740, barrel HV≥900

Hardening depth: 0.6-0.7mm: 0.6-0.7mm

Brittleness grade: ≤ 2 grade ≤ 2 grade

D. Gearbox: 173 involute cylindrical helical gear, alloy cast steel.

E. Die head material: 45 × 45 / high carbon steel

F. Temperature control by double digital display automatic temperature control meter

Optional options:

1: Rotary die head

2: double winder

3: Corona machine(if need printing)

4: auto suction

5: Meter and weight control

Parts List:

Heating ring: 4Pcs

Temperature Controller: 4pcs

Voltmeter: 4pcs

Thermocouple: 4pcs

Filter: 4 meter

Tools: 1set

Operation Manual: 1pcs

Đánh giá

Chưa có đánh giá nào.